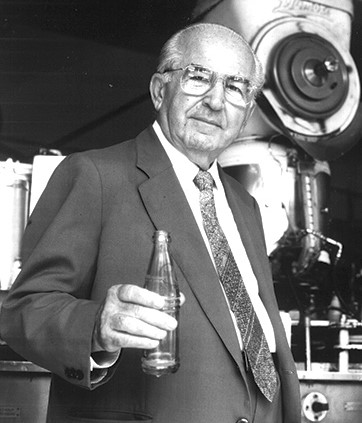

The late Takis Christodoulou, a pioneering young chemist with a specialized knowledge in fruit processing, founded KEA, the ‘Cyprus Soft Drinks Company’, in 1949, with the aim of extracting juices, essential oils and other natural ingredients from fresh citrus fruit. They would then be used for drinks, perfumes and cosmetics. The basic materials that were used were the indigenous aromatic herbs of the Cypriot countryside and the ripe varieties of Cypriot citrus fruit. To avoid confusion with another company with a similar name, in 1951 the company soon changed its name to KEAN SOFT DRINKS LTD.

Christodoulou perfected the juice extraction process by constant studying and understanding how the fruit should be handled during the growth, the crop and the juice extraction stages, avoiding over or under tipping, bruising, heating and also setting the rules for preserving naturally and storing the juice when concentrated. This is how he created the high standards and the ‘secret’ of KEAN soft drinks. The great fruity taste of the final product is based on the authentic taste and quality of the juice with all its natural characteristic of texture, aroma, colour, vitamins and minerals.

The specialized knowledge in the processing of citrus fruit soon gave the impetus for manufacturing a variety of orange, lemon and mandarin juice-based drinks, with a high juice content, on a large scale. The natural quality of the original fruit, the particularities of each taste and the fine processing of such sensitive fruit gave the best guarantee for the taste of the final product.

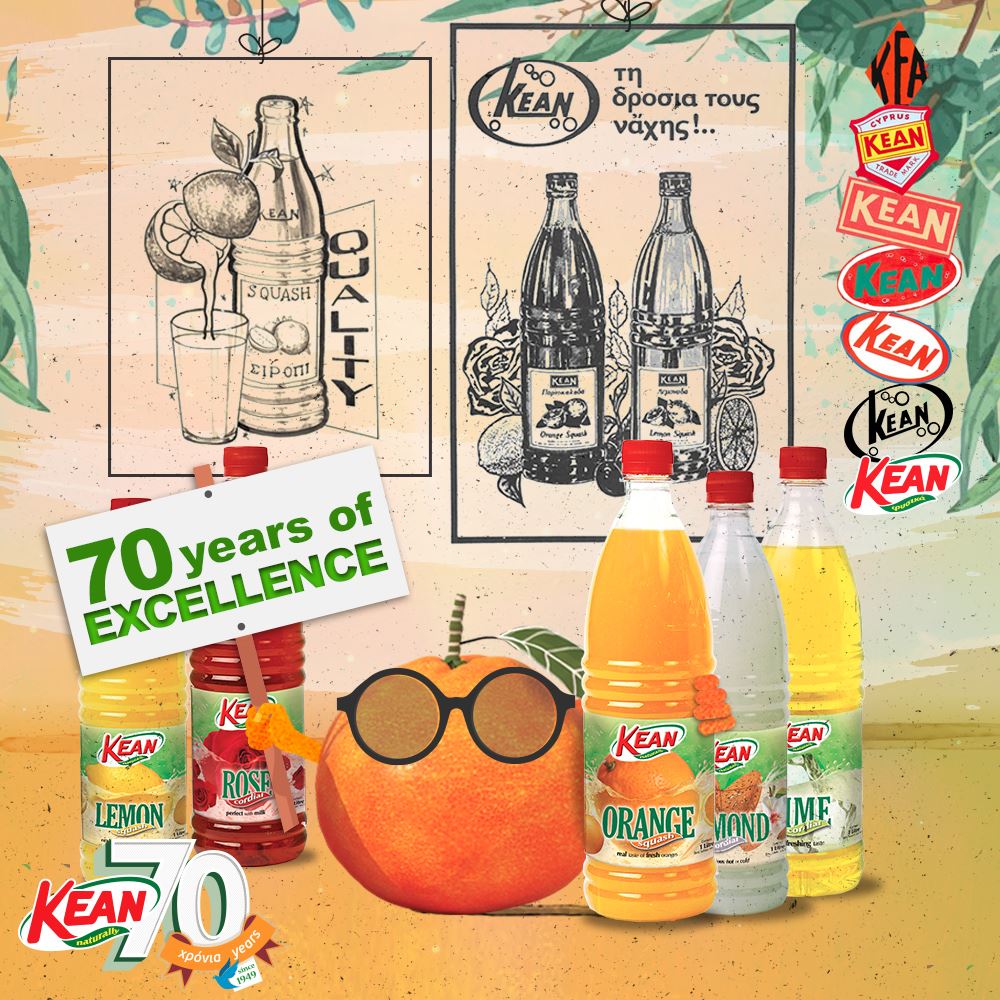

The first drinks to be produced were the squashes (orange, lemon, almond and sour cherry) with a high sugar content, which acted as a self-preserve ingredient. Soon the products were in great demand and the pressure for increasing production was strong.

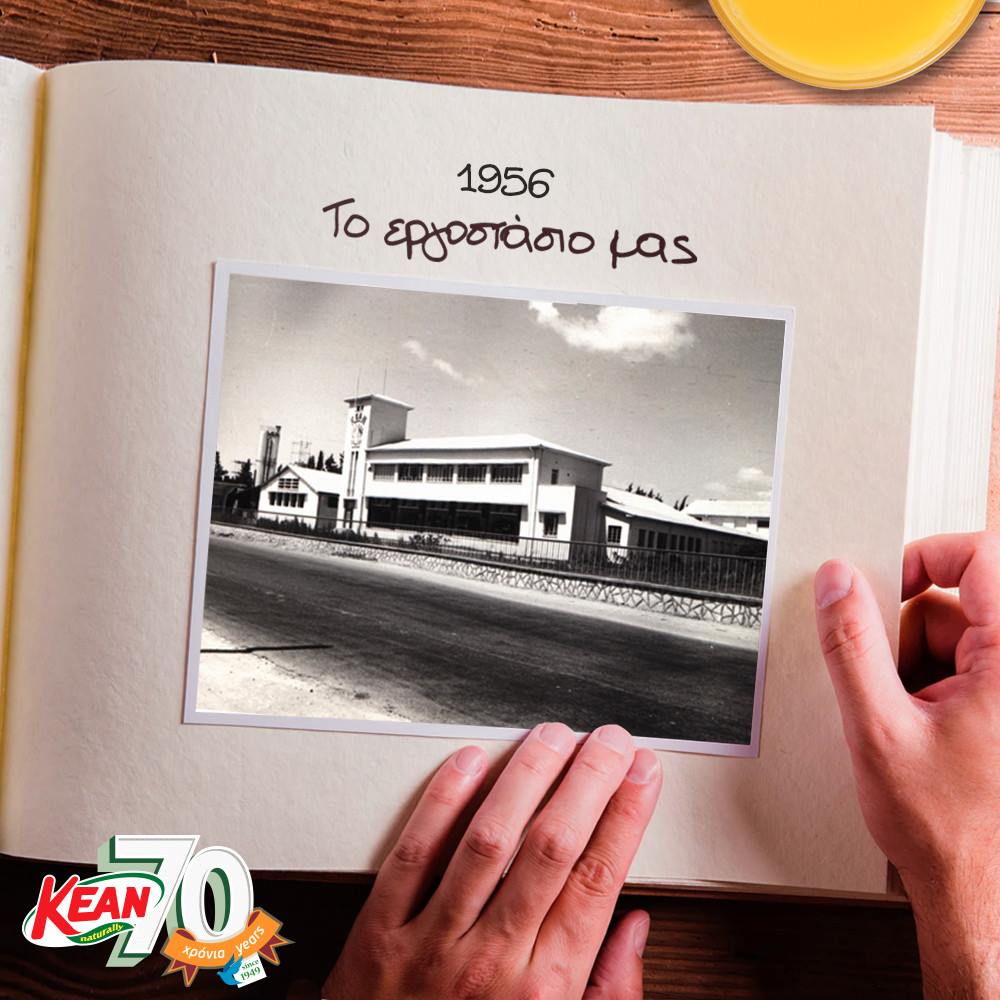

After changing location twice within Limassol, the construction of the KEAN factory commenced in 1951 and completed in 1956 to become a landmark that overlooks the Limassol seafront till today. The factory spreads over 40 acre and is located east of Limassol on the sea front, 10km away from the main port and 20km away from the fruit growing area. The two impressive gigantic mosaic bottles that stand guard at the gate are still there today, proudly emphasizing the presence of the factory with its Art Deco front; an architecture of a definite era.

KEAN was turning into a large and modern manufacturing unit and soon needed to incorporate new products in its portfolio. When an opportunity to distribute Pepsi Cola was presented, the company ‘Louca and Christodoulou’ was founded in 1959 to undertake the bottling of Pepsi Cola at the KEAN factory. A new partnership was launched and products of both brands were being distributed until 1972.

KEAN Soft Drinks Ltd continued its tradition with its own brands and also acquired licenses and bottling franchises from Canada Dry, Nichols International (Vimto), UK and Royal Crown Cola, USA.

During the struggling period after the Turkish invasion of Cyprus in 1974, when most of the fruit plantations were lost to the Turkish side together with the 37% of the island, Christodoulou, with his survival instinct, identified new export opportunities in the Near and Far East, for products not exclusively based on these raw materials. The company, who also lost a substantial part of its fleet, refrigerators and accounts, yet managed to survive and recover.

1981 was a cornerstone for KEAN. The company took the strategic decision to switch to innovative products and packaging and invested in modern machinery for packing juice in Tetra Pak cartons. This was a decisive step as KEAN became the first company in Cyprus and among the very few in the broader Eastern Mediterranean to proceed to such an investment. The combination of the expertise in processing the best natural raw materials together with the best final product quality as well as the latest packaging technology, established the KEAN brand as a leader in juices and fruit drinks.

Sustaining the momentum and maintaining its innovative strategy, KEAN continues to invest in the juice production infrastructure to allow for new products, new flavours and new packaging shapes to be developed. These factors continue to give the company direction and strength to grow with the times.